Product Descriptions

At almost the same strength as ordinary annealed glass of the same thickness,

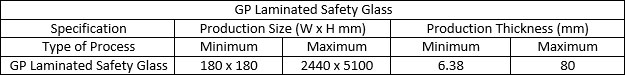

GP Laminated Safety Glass is produced by permanently bonding two or more sheets or glass with one or more sheets of tough Polyvinyl Butyral (PVB) interlayers under heat and pressure.

GP Laminated Safety Glass is supplied to comply with either of the following standards where specified:

1. BS 6206:1981

2. AS/NZS 2208:1996

Product Features

Sound Reduction:

GP Laminated Glass is an excellent barrier to noise as it provides a dampening effect on the transmission of sound.

Safety & Security:

If broken, the laminated safety glass will remain firmly bonded to the PVB interlayer, minimizing the risk of injuries while providing protection and resistance to entry and safeguarding the broken area until replaced.

UV Control:

Screening out almost all the sun’s damaging UV,

GP Laminated Glass will provide protection against fading, deterioration of furnishing and artwork caused by UV radiation.

Versatility:

Available in a wide variety of design options,

GP Laminated Safety Glass may be made with a variety of annealed, heat strengthened, tempered, reflective or Low-E glass, depending on the design needs.